Tu sei qui

Calculating the amount of materials for the manufacturer

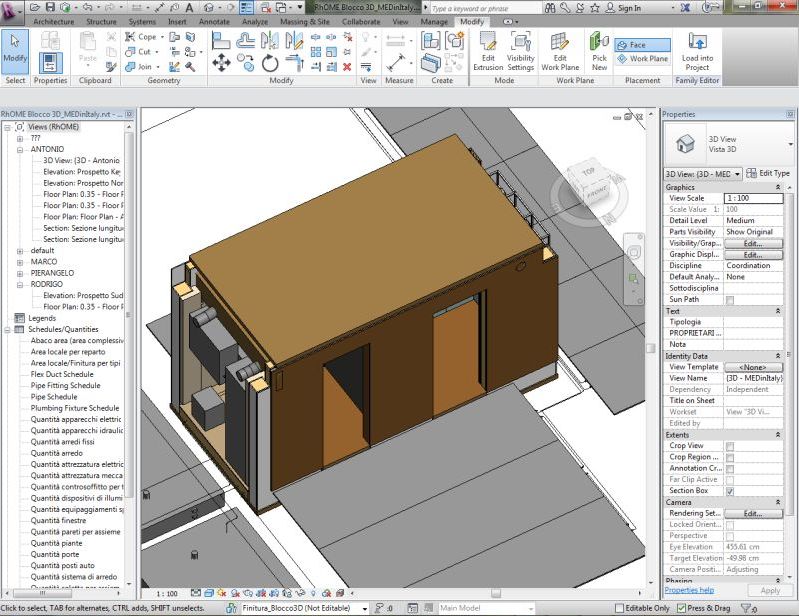

Since we had to deliver promptly area calculations of materials that the manufacturer of our home have to order we had to model quickly each missing surface (these are mainly finishing materials).

Having lack of time and being it our only urgent need we chose to model family types as large as each wall.

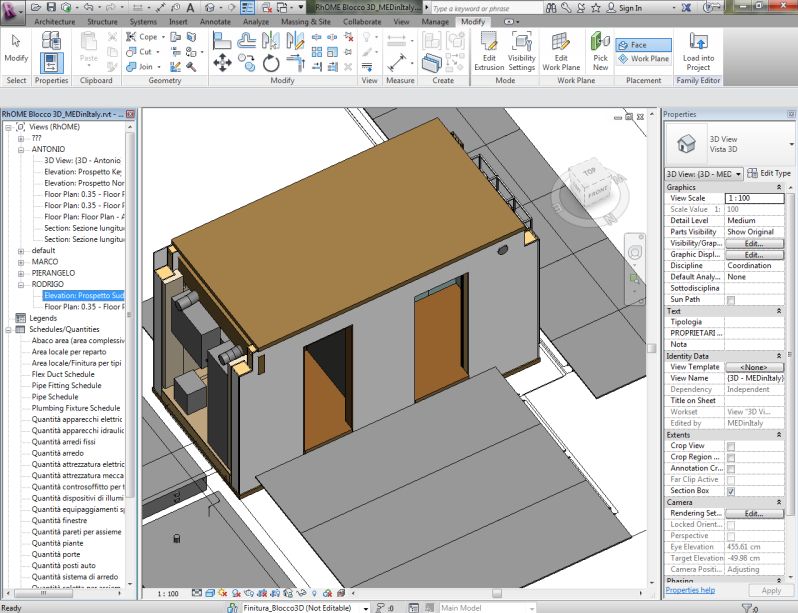

In the example below I chose to show the north wall of the 3D Core that lacked of the finishing coating in wood

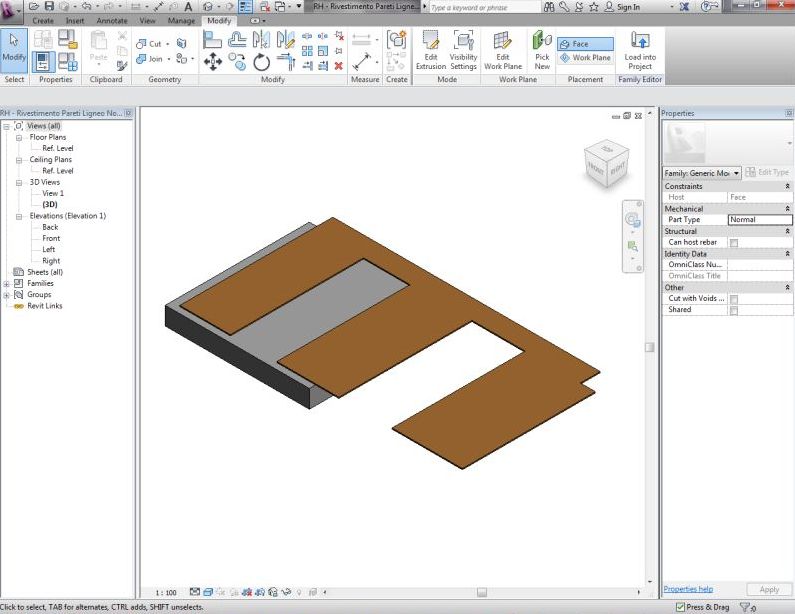

Making of the family of the finishing coating for north wall

Loading of the family in the 3D Core project

The family has been correctly based on the right workplane (a well-named reference plane) and aligned to some other named reference plane

We are well aware that later time we'll have to replace these unique surfaces with panels with well-considered sizes.

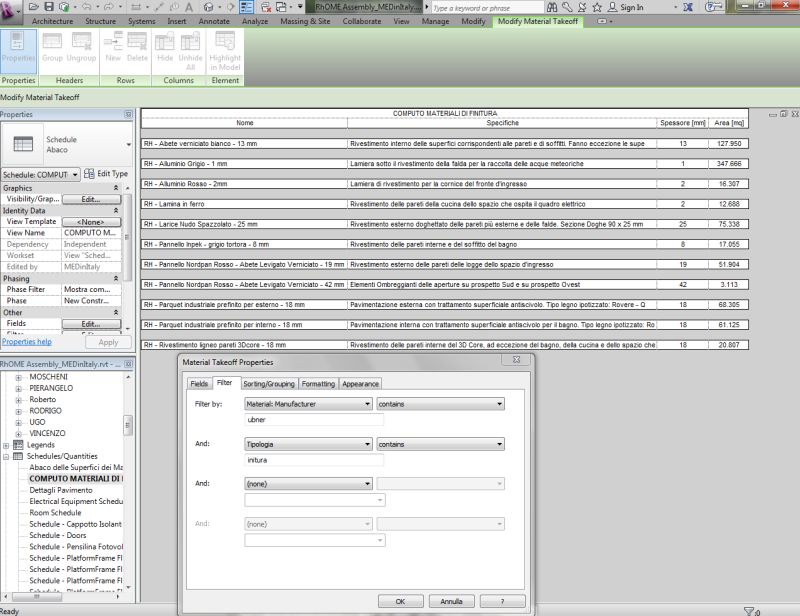

These new families have been equipped with some shared parameters concerning type and manufacturer related to material. In this way we were able to form a dynamic schedule where it's easily possible to filter according to the type and the manufactorer. The data area is a calculated value obtained from volume/thickness (a project parameter linked to the material). Here is the configuration of the schedule we have exported and sent to the manufacturer of the home.