Five points towards a new architecture | 4 - Eco-conscious

Published by GiuliaPanadisi on Mon, 05/12/2011 - 17:12Five points towards a new architecture | 4 - Eco-conscious

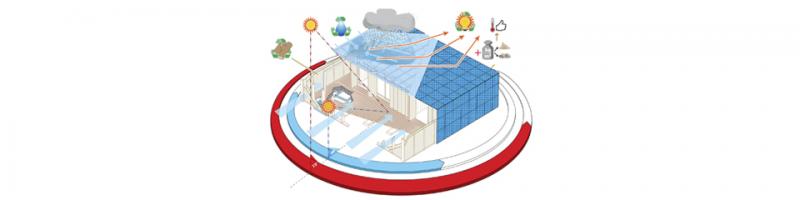

To conceive a sustainable house means for sure to minimize energy needs for reaching comfort conditions, and build a system of production of alternative energy able to feed entirely those needs.

But this is not enough.

The Medinitaly project takes into account the global quantity of primary energy embodied in all materials, components and processes included in manufacturing, transportation and erection of the building. According to this information, during the design process alternatives are evaluated with the aim of reaching the highest level of global sustainability of the construction.

|

|

A special attention has been paied to sustainability of the house materials, mostly renewable, such as wood (constructive and structural system) and rattan (shadowing, façade finishing and fence walls). The windows glasses derive from recycled glass.

Light wooden frames will become heavy massive walls thanks to the possibility to fill them up with local heavy materials, such as sand, ground, gravel and so on. This permits to save sand or gravel because they don’t mixed with other materials and could so be reused in case of disassembly. Fur¬thermore, not for the contests’ weeks it will be possible to employ also debris, helping to decrease rubble dump.

The PV panels lean on an aluminum structure. They are CIS panels. “CIS” technology, denoting key ingredients copper, indium and selenium (together with gallium and sulfur), has the best potential to set the world’s most enduring standard for solar energy. CIS modules require fewer manufactu-ring steps, less materials, and contain no cadmium and no lead. CIS modules require less energy to produce — 60% less than the current industry standard crystalline silicon, with an Energy Payback Time under one year. CIS cells are typically 100 times thinner than crystalline cells, requiring less na¬tural resources. The manufacturing process for a complete module involves significantly fewer steps, with the entire process happening under one roof — from raw materials to finished product.

We are now evaluating the possibility to substitute the low density insulating material in the exterior walls with cellulose coming from recycled paper. Cellulose can be easily inflated and guarantees similar performance in terms of transmittance.