Tesi master theses

Devoto fabrication partner

CNC: real experiences | case studies

Acoustics projects | form | analisys

Custom Families Revit

Data Production model to data

Visual Basic scripting for Revit

Barrisol project for a conferece hall

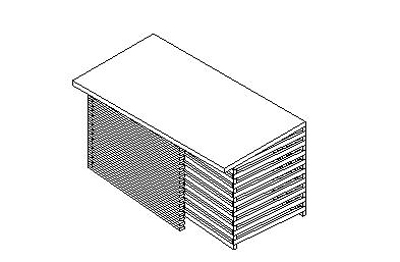

The work was focused on a furniture that could fit in the university life. I started working on a desk, then i designed a showcase for the university yard.

I struggled a little bit on this work because I was thinking what is the meaning of this work, of working with this parametric softwares in this parametric\mass customization dimension.

What I did ask to myself was if it just means to go over the orotogonality as design value (in its connection with the production process) . Looking exaples I match two different approaches: first is the one we watched in the most of the exaples of architecture offices working with in these ways, it gets easily to the "blob", the second is what it is in the production farm where it's just used as instrument in the simple furnitures.

What I recognised is the exclamation point of those new way of working is maybe in the mid point between those position. Considering a real design work what grow up mostly to me is the process, intending all those back and forth we usually do in the planning process, things that, with parametric, are always checked together, without the need of the back and forth that we are used to play in standard design. This is just to underline what is to me the point more than just the skill to overcome ortogonality.

First work is a desk. I mostly worked on the structure of it. At the begining it was composed by one piece zig-zag elements, in a second momento, thinking to production, i realized that could be better to scompose the shape into bar. Finally instead realizing an orizzontal structure composed by orizzontal bars and verticals (structure), I used just orizzontal, folding them in the in their end section by interlocking. The object is composed by the desk orizzontal board and by the bars that are all types of the same family.

In the second part of the assignment I worled on a showcase, thought to fit in the university yard and to answer to the need of showcase and together of meeting points with some bench for the students. I made different families: one is the orizzontal structure, the others are for the board and for the elements of the benches. In a first moment the furniture wasn't regular but it was rotated in different poits with the aim to be selfstructural, then, thinking to production it would have bring more lost of material considering the starting board.

The element is composed on the vertical board of the showcase that are together the vertical structure and the orizzontal elements that link all the furniture. The benches lean on these orizzontals and they also work to avoid flipping.

I'd like to put down an estimation and to draw the production boards with the pieces on but I had problems about this step.

(Ma dovevo scrivere in inglese o no?!?)

commenti

StefanoConverso

9 Gennaio, 2009 - 12:31

Collegamento permanente

Images of the twisted hypotesis

Tommaso,

great to read you and see your post.

I agree with most of what you say,

then I think it would be useful to see some images of the "twisted" hypotesis of your design intention.

I think the idea of the University as context works really well. Don't worry of possible absurde hypoteses of assembling, we will discuss those issues with Claudio Devoto in the classroom, based on the proposals that you all will make.

As you saw, it is possible to work also tridimensionally on the boards, by milling those, and also to glue some of the pieces.

a domani,

Stefano

p.s.

ok to write in English.

use "full html" to get your text formatted.

can you show some of your Revit process to achieve this?