Tesi master theses

Devoto fabrication partner

CNC: real experiences | case studies

Acoustics projects | form | analisys

Custom Families Revit

Data Production model to data

Visual Basic scripting for Revit

Barrisol project for a conferece hall

After Devoto's review we cleared some points of my questions on designing in mass customization / parametric context. I also felt to need a step back, focusing again on the formal concept that drove me in the design process.

The matrix of my showcase was the wall as meaning of a vertical, close boundary. The shift, the wreck has a double meaning: a new space that changes the meaning of the wall, switching it from limit to space-through, a movement structurally needed to mantain balance.

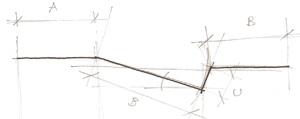

The line in the sketch shows the orizzontal wood board structure, this has just the role of binding together the all object. The vertical forces are brought by the panels. The next step was to think about position of those panels, always keeping in mind the matrix concept of the shifted wall.

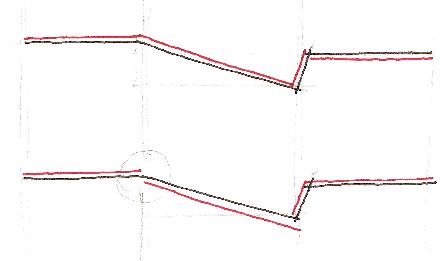

The sketches show two options, in red is the position of the vertical panels. My aim was to show as better as possible the wreck of the plane with a binary systema made of surface (panel) and void (where panel is not up and we can see the orizzontal structure).

The other theme that pop up from the review was about the meaning of production in this logic of parameters: I asked if it will just carry us to design "blobs" because we can now build those without too much problems or if it something else.. What emerged from this discussion was that an interesting point could be to find a detail where the new production context can show us in a quite traditional, "regular" object. These elements had been identified into nodes between elements: the connection of orizzontal board where the structure bends and the tail of the panels.

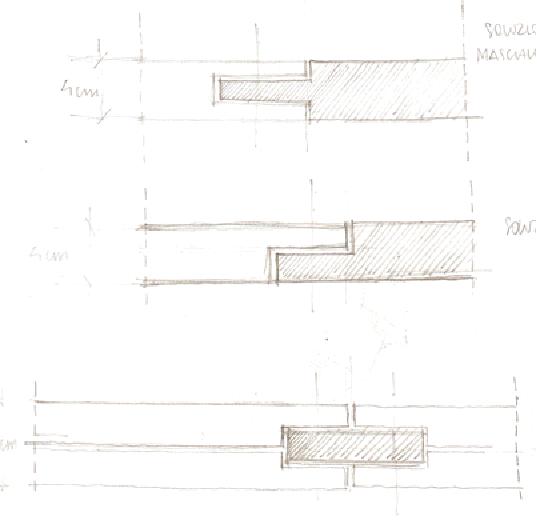

First point is about connection of orizzontal beams: here I didn't want just to lean the boards one on the other, so I tryed to think how to cut pieces in order to joint them together. Of those ideas (thinking to elevations too) I liked more the last two, but finally I chose the middle one also because last one would mean a bigger waste of wood.The chosen option works on the two boards shaped with two L and so workink joined together and linked with a metal pivot. I must underline that, switching idea from the beginning, the project is not anymore in a user customization logic: the showcase is fixed and not able to rotate.

Second point of this speech is the orizzontal section definition of crossing between orizzontal boards. In the corner we have multiple themes: wich board is the leader of the two and do they keep ortogonality of the board or not (basically, do we see corners out of the crossing or not?)??

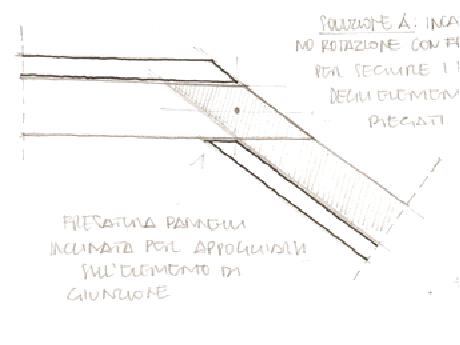

In this drawings are faced two problems: this one about design of ending section of the boards and the one about the design of panels tail. The first problem aswer is with the boards that follow the bend of the structure: there are not ortogonal cuts and in any node of the structure the boards have different angle cut one from the other. This is where customization rules.

The other question is about this two different solution for the position of panels. The first one is with panels that are on the opposite sides of the orizzontal structures, the ending section of panel has an oblique cut that follow the fold of the structure in order to lean on it. In this second drawing the panels are on the same side of the structure and the cut want to show them as a continous surface just folding to follow the form of the object.

I did this small step back because I wasn't satisfyed about the formal aspects of my design, it seemed I lose a little bit my path. Now I put together my first formal ideas with the output given from the review and from production notes. As soon as I can I will put those thoughts on Revit to watch better wich is the result.

Commenti recenti