Tesi master theses

Devoto fabrication partner

CNC: real experiences | case studies

Acoustics projects | form | analisys

Custom Families Revit

Data Production model to data

Visual Basic scripting for Revit

Barrisol project for a conferece hall

Since we have a limited amount of wood and i prefer the puf solution (27cm heigh sitting), i'm about to give quantities starting from this. This preliminary schedul is essential for the design: After assembling my acoustic chair, i'm expecting to be able to produce a schedule identical to this from the revit model. I've produced separate alements in order to obtain the volume schedule, because i thought that revit recognizes volume as a inner propriety of the solids....not like this.

.jpg)

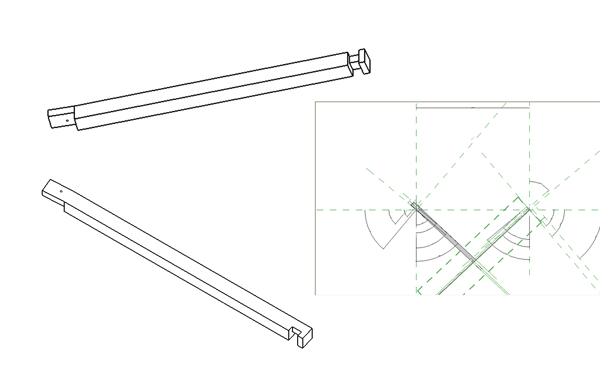

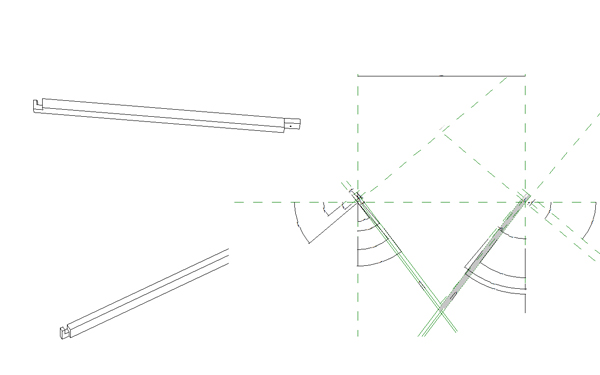

All the sistem is beared and jointed by 3 steel circular bars

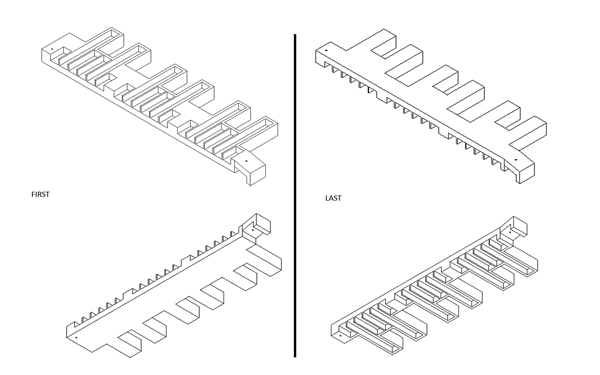

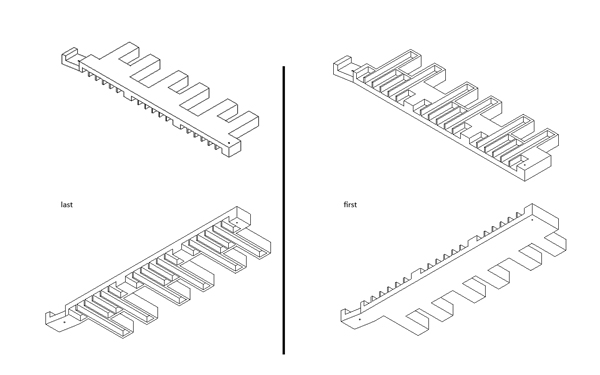

1_base elements

The base is composed by four elements jointed together, each level.

These two elements provide the front of the base. they have a small variation which will be given in the assembly.

These elements are the real "foundations" of the whole system, they're the heaviest. The first one has a small home for the knot which carries the steel bar.

.jpg)

I've imagined the sitting as a monolitic piece.

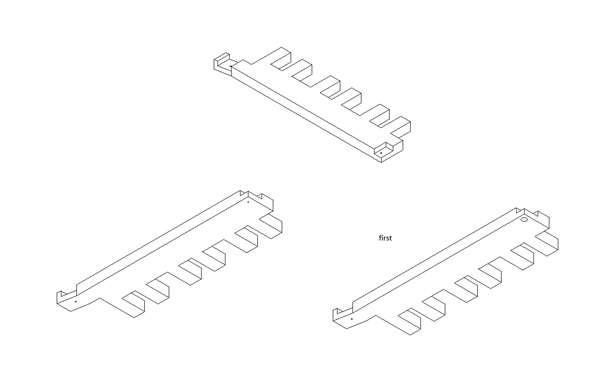

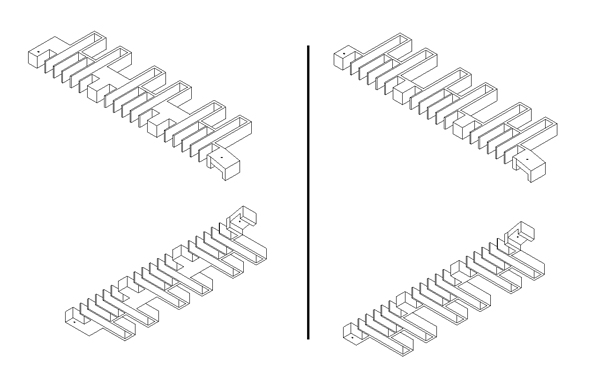

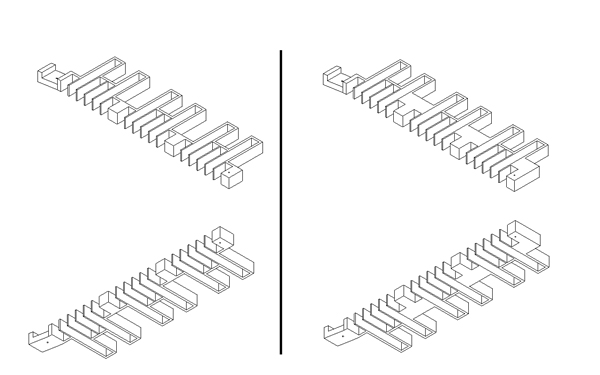

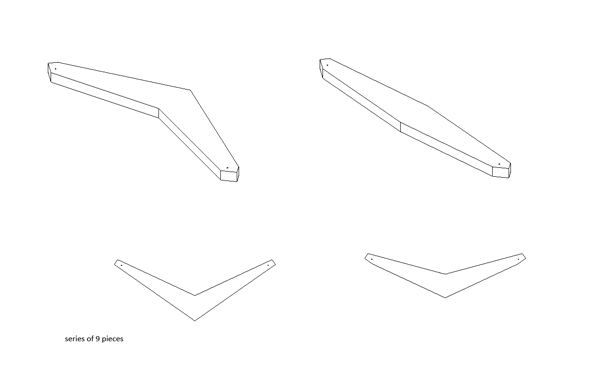

2_RPG elements

a number of identical pieces produces the rpgs. After the nesting post (this evening, i hope) it will be clear the reason for which 've designed these elements like this.

The two versions of the same element have their weight different, because of the nesting. Heavier elements are in the bottom

These special elements are necessary to close the gaps.

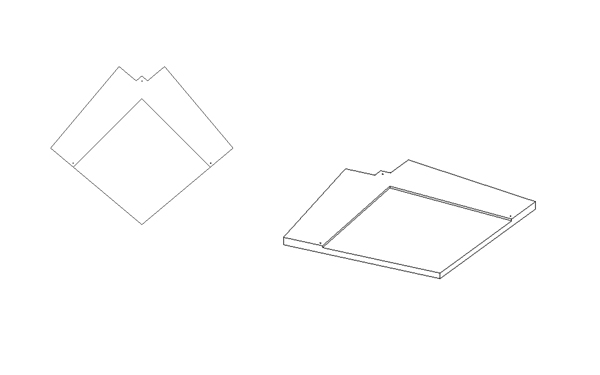

3_ top

the top is as well produced by a single element variating

Commenti recenti